Leaf springs ke karolo ea bohlokoa ea tsamaiso ea ho emisa koloi, e fanang ka tšehetso le botsitso.E le ho mamella khatello le khatello e sa khaotseng eo ba e mamellang, liliba tsa makhasi li hloka ho thatafatsoa le ho halefa ho netefatsa hore li tšoarella le ho phela nako e telele.Ho thatafatsa le ho futhumatsa ke mekhoa e 'meli ea bohlokoa e sebelisetsoang ho matlafatsa thepa le ho ntlafatsa thepa ea eona ea mochine.Sehloohong sena, re tla hlahloba mekhoa ea quenching, tempering, le tšebeliso ea bona ho thatafatsa le ho futhumatsa liliba tsa makhasi.

Ho timake ts'ebetso e kenyelletsang ho futhumatsa thepa mochesong o phahameng ebe o e pholisa ka potlako sebakeng sa mokelikeli, joalo ka metsi kapa oli.Pholiso ena e potlakileng e etsa hore thepa e be thata, e eketsa matla le ho tiea ha eona.Ha ho tluoa tabeng ea liliba tsa makhasi.quenchinge atisa ho sebelisoa ho eketsa ho tiea ha tšepe, ho etsa hore ho be thata ho apara le ho khathala.Mokhoa o khethehileng oa ho tima o sebelisoang bakeng sa liliba tsa makhasi o itšetlehile ka ho hlophisoa ha tšepe le thepa e lakatsehang ea mochine.

Kamora ts'ebetso ea ho tima, thepa e ba thata haholo ebile e brittle.E le ho fokotsa brittleness ena le ho ntlafatsa ho tiea ha lintho tse bonahalang, tempering e etsoa.Ho futhumatsa ho akarelletsa ho futhumatsa ntho e tingoeng mochesong o tlaase ebe o e pholisa butle.Ts'ebetso ena e lumella likhatello tsa kahare ka har'a thepa hore li fokotsehe, e leng se etsang hore ho be le ductile e ngata le e fokolang haholo.Tempering e boetse e thusa ho ntlafatsa khanyetso ea thepa ho ts'usumetso le ho ts'oaroa ha makala.

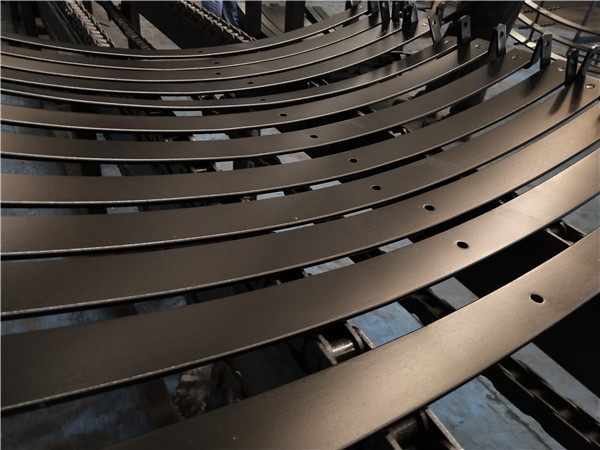

Ts'ebetso e thata le e futhumatsang bakeng sa liliba tsa makhasi e qala ka khetho ea motsoako oa tšepe o loketseng.Lisebelisoa tsa tšepe tse sebelisoang ka tloaelo bakeng sa liliba tsa makhasi li kenyelletsa 5160, 9260, le 1095. Li-alloys tsena li khethiloe ka lebaka la matla a tsona a phahameng, ho hanyetsa mokhathala, le bokhoni ba ho mamella meroalo e boima.Hang ha tšepe e khethiloe, e futhumatsoa ho mocheso o itseng o thehiloeng ho motsoako oa motsoako ebe o tima ka mokhoa o loketseng ho finyella boima bo lakatsehang.

Ka mor'a ho tima, thepa e ntan'o halefa ka matla a hlokahalang le ho tiea.Thempereichara ea mocheso le nako li laoloa ka hloko ho finyella lintho tse lakatsehang tsa mochine, tse kang ho thatafala, matla le ductility.Sephetho sa ho qetela ke selemo sa makhasi se matla, se tenyetsehang, 'me se khona ho mamella mathata a ts'ebetso e boima.

Ho thatafatsa le ho kokobetsaea liliba tsa makhasi ke ts'ebetso ea bohlokoa e hlokang ho nepahala le boiphihlelo.Ho tima le ho kokobetsa ka mokhoa o sa lokelang ho ka lebisa litabeng tse fapa-fapaneng, tse kang ho petsoha, ho phunya, kapa ho thatafalloa ho lekaneng.Ka hona, ho bohlokoa ho latela mekhoa e metle ea indasteri le ho latela mehato e tiileng ea taolo ea boleng ho etsa bonnete ba hore liliba tsa makhasi li fihlela litlhoko tse hlokahalang.

Qetellong, ho thatafala leho kokobela hoa makhasi a makhasibapala karolo ea bohlokoa ho netefatsa ts'ebetso ea bona le bophelo bo bolelele.Motsoako oa mekhoa ea ho tima le ho futhumatsa e fella ka boitsebiso bo thata le bo thata, bo etsang hore bo tšoanele maemo a boima ao liliba tsa makhasi li tlas'a tsona.Ka ho utloisisa mekhoa ea ho tima le ho futhumatsa le ho sebelisoa ha bona ho thatafatsa le ho futhumatsa liliba tsa makhasi, bahlahisi ba ka hlahisa liliba tsa makhasi a boleng bo phahameng, tse ka tšeptjoang tse finyellang litlhoko tsa mefuta e sa tšoaneng ea likoloi le liindasteri.

Nako ea poso: Dec-11-2023